PLC Trining System

YPLC-1000 , YPLC-2000 , YPLC-2100 , YPLC-2200 , YPLC-2300 , YPLC-TSJ-1000 , YPLC-TSJ-2000

Product name: PLC Training System Model: YPLC-1000

Features

■ Basic PLC trainer for electric and electronic students

■ Basic PLC training and application based on wiring as needed

■ Separate PLC application modules

■ Practice of temperature control, traffic signal control, level control, conveyer control and parking control

■ Application practice using HMI

■ A slop design with 10 degrees inclined toward students, providing a convenient test environment

■ A self-diagnosis program, facilitating equipment management

Specification PLC Trainer Body) - DC Output: 0 ~ 24V / 0 ~ 5A, 0 ~ 12V / 0 ~ 5A PLC Unit) - CPU - Base - Power Module - Input Module - Output module Input & Output Unit) - Buzzer: 1 Ea - Tower Lamp: 1 Ea - Output Terminal: 60 Ea - Case Temperature Control Unit) - Case: Insulated plastic injection case - Digital temperature display - Built-in-over-heat protection device Traffic Control Unit) - Case: Insulated plastic injection case - Practice control of various crossroad signals Level Control Unit) - Case : Insulated plastic injection case - Enclosed water-proof structure - Safety accident preventative structure - Embedded controller Conveyer Control Unit) - Multi-step control (5 steps or more) - Sample materials: 10 types or more - Material loading to inlet (5 types or more) - Sample material (MC or acetel) - Conveyer driving motor (Serial roller connection) - Conveyer belt self-aligning capability - Various sensor convers - Material deposit warehouse Parting Area Control Unit) - Parking capacity: 4 cars or more - Cross bar auto up/down control with a 3-step control sensor detecting motion of model cars - Check-in/Check-out counter and display - Parking and full sign Touch Screen Module) - Touch Screen - LCD: 7 inch - Input Power : DC 24V - Case : Aluminum case - Front panel: Aluminum 2t - Terminal: TOOL, USB, LAN, RS232/422/485 1 Ea - Power: DC 24V Available Wiring Assemblies: 300 Ea

Training Contents Part 1. PLC Control Circuit 1. Basic Understanding of PLC 2. Practice of PLC Program Part 2. Industrial Instrument Control Circuit (Including various examples) 1. Application practice using LED Output 2. Application practice using sensors 3. Application practice using models 4. Application practice using industrial instruments 5. Practice for understanding auto control mechanism Part 3. HMI Control 1. HMI General 2. HMI Control Part 4. Description of PLC Commands 1. Basic commands 2. Application commands Part 5. Elements Required for System Manufacturing 1. Input elements 2. Output elements Part 6. My Project 1. Project Format

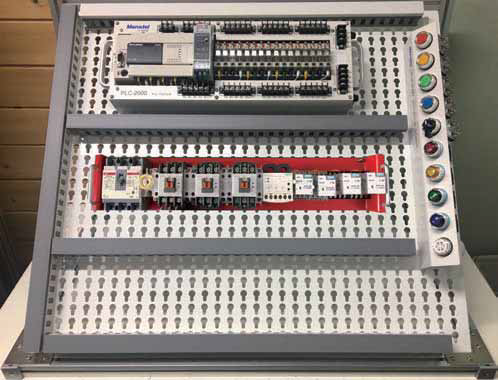

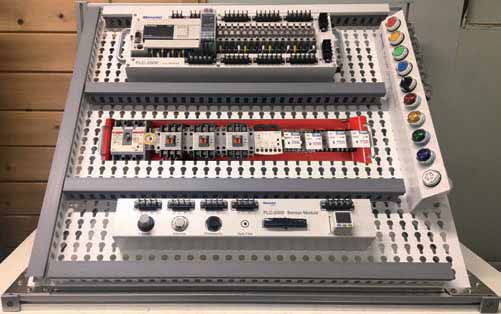

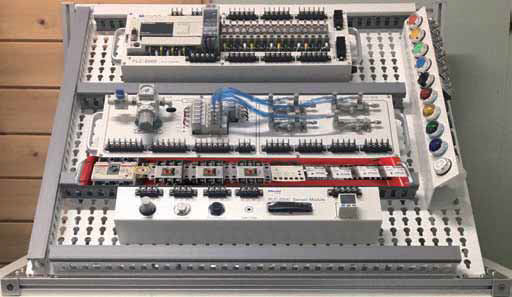

Product name: PLC with IoT Training System Model: YPLC-2000

Features

■ IoT based MITSUBISHI FX3u-32MR PLC

■ Control practice utilizing IoT Internet of Things WiFi communication

■ Experimental practice of basic programming command and various application program command

■ MITSUBISHI FX-PLC program and Operation experimental practice

■ Practice applied with Sequence module

■ Practice applied with switch module

■ Practice applied with sensor module

■ Practice applied with pneumatic module

■ Practice control applied with touch screen drawing

Specification

PLC Unit)

- Power: AC100~240V

- Input: 16 ea (DC 24V sink/source input)

- Output: 16ea (relay) : 2A/1ea(8A/4ea) below AC250V DC30V

Switch Module Unit)

- Switch: Ø25 (Red, Yellow, Green, Blue)

- Lamp: Ø25,4ea(Red, Yellow, Green, Blue ), 25VDC

- Buzzer: Ø25 , 24VDC, 65dB(distance 1m),

Sensor Module Unit)

Capative

- power supply voltage: DC12~24V(DC10~30V)

- Detection distance: 8mm±10%

Inductive

- power supply voltage: 12~24VDC

- Detection distance: 5mm±10%

Photoelectricity

- power supply voltage: 10~30VDC

- Detection distance: 100mm

- flood lamp spot diameter: 40 x 45mm

fiber

- operating temperature: -40 ~ 70°C

- sensing distance : 7.5cm

Preassure Sensor

- power supply voltage : 12~24VDC±10%

- rated pressure range : -0.100 ~ +1.000MPa

Sequence Module Unit)

Molded case circuit breaker

- rated voltage: AC460V

- rated short circuit: 2.5KA

- rated current: 30A

- outer size: 75x96x60mm

Electronic overcurrent relay

- current setting: 3.0 ~ 30A

- operating voltage: 24~240V AC/DC (50/60Hz)

Electromagnetic contactor

- rated current: 32, 40A

- rated operational voltage: 690V

- rated insulation voltage: 1000V

Content Specification

- Rated current : 10A 30VDC / 10A 250VAC

- Max. switching voltage : 250VAC/10A, 2.5VDC/1.5A

Coil specification

- voltage specification: 12VDC, 24VDC, 100/110VDC, 12VAC 50/60Hz, 24VAC 50/60Hz

- Max . cut-off voltage : DC : 10% of rated voltage AC: 30% of rated voltage

- Max. Voltage: 110% of rated voltage

Pneumatic Module Unit)

Single-acting cylinder

- Max. pressure: 1.5MPa/102PSI

- Bore : 10mm/0.39in

- Stroke : 15mm/0.6in

- Road Diameter : 4mm/0.16in

- Weight : 30[g]

Double-acting cylinder

- Max. pressure: 1.5MPa/102PSI

- Bore : 10mm/0.39in

- Stroke : 15mm/0.6in

- Road Diameter : 4mm/0.16in

- Weight : 30[g]

Dipolar Rely Module Unit)

- Rated voltage: AC460V

- Rated short circuit: 2.5KA

- Rated current: 30A

- Outer size: 50x96x60mm

WiFi Communication Module Unit)

- Power source : DC3.3V

- WLAN standard : IEEE 802 11 b / g / n

- 1MB Flash Memory, 128KB SRAM, 1MB Serial Flash

IoT Communication Module Unit)

- Power source : DC24V

- PWM(D/A) : 4points

- communication : TTL232/RS232/SPI/I2C

- Outer size : 128.5 x 77.5mm

AC In-/output) 220V DC Output) 0~24V

Training Contents Chapter 1. PLC summary Chapter 2. PLC structure Chapter 3. PLC wiring and command Chapter 4. FX-PLC composition Chapter 5. GX Developer operating Chapter 6. PLC basic command Chapter 7. PLC numerical data Chapter 8. Application command and programming Chapter 9. programming learning Chapter 11. Sensor module control practice Chapter 12. Pneumatic module control practice Chapter 13. HMI drawing design and control test Chapter 14. IoT summary and Hardware structure Chapter 15. IoT Internet of Things based control practice Chapter 16. PLC application control practice

Product name: Basic PLC Training System Model: YPLC-2100 Feature

■ MITSUBISHI PLC Experiment and Practice Equipment

■ Basic program command and various application program command experiment and practice

■ MITSUBISHI FX-PLC Program and Operation Experiment and Practice

■ Practice using Sequence module

■ Practice using switch module

■ IoT based MITSUBISHI FX3u-32MR PLC

■ Control practice utilizing IoT Internet of Things WiFi communication

■ Experimental practice of basic programming command and various application program command

■ MITSUBISHI FX-PLC program and Operation experimental practice

■ Practice applied with Sequence module

■ Practice applied with switch module

■ Practice applied with sensor module

■ Practice applied with pneumatic module

■ Practice control applied with touch screen drawing

Specification

PLC Unit)

- Power: AC100~240V

- Input: 16 ea (DC 24V sink/source input)

- Output: 16ea (relay) : 2A/1ea(8A/4ea) below AC250V DC30V

Switch Module Unit)

- Switch: Ø25 (Red, Yellow, Green, Blue)

- Lamp: Ø25,4ea(Red, Yellow, Green, Blue ), 25VDC

- Buzzer: Ø25 , 24VDC, 65dB(distance 1m),

Sequence Module Unit)

Molded case circuit breaker

- rated voltage: AC460V

- rated short circuit: 2.5KA

- rated current: 30A

- outer size: 75x96x60mm

Electronic overcurrent relay

- current setting: 3.0 ~ 30A

- operating voltage: 24~240V AC/DC (50/60Hz)

Electromagnetic contactor

- rated current: 32, 40A

- rated operational voltage: 690V

- rated insulation voltage: 1000V

Content Specification

- Rated current : 10A 30VDC / 10A 250VAC

- Max. switching voltage : 250VAC/10A, 2.5VDC/1.5A

Coil specification

- voltage specification: 12VDC, 24VDC, 100/110VDC, 12VAC 50/60Hz, 24VAC 50/60Hz

- Max . cut-off voltage : DC : 10% of rated voltage AC: 30% of rated voltage

- Max. Voltage: 110% of rated voltage

AC In-/output) 220V DC Output) 24V

Training Contents Chapter 1. Outline of PLC Chapter 2. Structure of PLC Chapter 3. PLC wiring and command Chapter 4. Composition of FX-PLC Chapter 5. Operation of GX Developer Chapter 6. Basic command of PLC Chapter 7. Numerical data of PLC Chapter 8. Application command and programming Chapter 9. Learning programming Chapter 10. Sequence control practice Chapter 11. PLC application control practice

Product name: PLC Training System Model: YPLC-2200

Feature

■ MITSUBISHI PLC Experiment and Practice Equipment

■ Basic Program Command and Diversified Application Program Command Experiment and Practice

■ MITSUBISHI FX-PLC Program and Operation Experiment and Practice

■ Practice using Sequence module

■ Practice using switch module

■ Practice using sensor module Specification

PLC Unit)

- Power: AC100~240V

- Input: 16 ea (DC 24V sink/source input)

- Output: 16ea (relay) : 2A/1ea(8A/4ea) below AC250V DC30V

Switch Module Unit)

- Switch: Ø25 (Red, Yellow, Green, Blue)

- Lamp: Ø25,4ea(Red, Yellow, Green, Blue ), 25VDC

- Buzzer: Ø25 , 24VDC, 65dB(distance 1m),

Sensor Module Unit)

Capative

- power supply voltage: DC12~24V(DC10~30V)

- Detection distance: 8mm±10%

Inductive

- power supply voltage: 12~24VDC

- Detection distance: 5mm±10%

Photoelectricity

- power supply voltage: 10~30VDC

- Detection distance: 100mm

- flood lamp spot diameter: 40 x 45mm

fiber

- operating temperature: -40 ~ 70°C

- sensing distance : 7.5cm

Preassure Sensor

- power supply voltage : 12~24VDC±10%

- rated pressure range : -0.100 ~ +1.000MPa

Sequence Module Unit)

Molded case circuit breaker

- rated voltage: AC460V

- rated short circuit: 2.5KA

- rated current: 30A

- outer size: 75x96x60mm

Electronic overcurrent relay

- current setting: 3.0 ~ 30A

- operating voltage: 24~240V AC/DC (50/60Hz)

Electromagnetic contactor

- rated current: 32, 40A

- rated operational voltage: 690V

- rated insulation voltage: 1000V

Content Specification

- Rated current : 10A 30VDC / 10A 250VAC

- Max. switching voltage : 250VAC/10A, 2.5VDC/1.5A

Coil specification

- voltage specification: 12VDC, 24VDC, 100/110VDC, 12VAC 50/60Hz, 24VAC 50/60Hz

- Max . cut-off voltage : DC : 10% of rated voltage AC: 30% of rated voltage

- Max. Voltage: 110% of rated voltage

AC In-/output) 220V DC Output) 24V

Training Contents Chapter 1. Summary of PLC Chapter 2. PLC Structure Chapter 3. Wiring and command of PLC Chapter 4. Composition of FX-PLC Chapter 5. GX Developer Operation Chapter 6. Basic Command of PLC Chapter 7. PLC Numerical data Chapter 8. Application Command and Programming Chapter 9. Learning Programming Chapter 10. Sequence control practice Chapter 11. Sensor module control practice Chapter 12. PLC Application Control Practice

Product name: PLC Training System Model: YPLC-2300 Feature

■ MITSUBISHI PLC Experiment Practice Equipment

■ Basic Program Command and Diversified Application Program Command Experiment Practice

■ MITSUBISHI FX-PLC Program and Operation Experiment Practice

■ Practice applying Sequence Module

■ Practice applying Switch Module

■ Practice applying Sensor Module

■ Practice applying Pneumatic Module. Specification

PLC Unit)

- Power: AC100~240V

- Input: 16 ea (DC 24V sink/source input)

- Output: 16ea (relay) : 2A/1ea(8A/4ea) below AC250V DC30V

Switch Module Unit)

- Switch: Ø25 (Red, Yellow, Green, Blue)

- Lamp: Ø25,4ea(Red, Yellow, Green, Blue ), 25VDC

- Buzzer: Ø25 , 24VDC, 65dB(distance 1m),

Sensor Module Unit)

Capative

- power supply voltage: DC12~24V(DC10~30V)

- Detection distance: 8mm±10%

Inductive

- power supply voltage: 12~24VDC

- Detection distance: 5mm±10%

Photoelectricity

- power supply voltage: 10~30VDC

- Detection distance: 100mm

- flood lamp spot diameter: 40 x 45mm

fiber

- operating temperature: -40 ~ 70°C

- sensing distance : 7.5cm

Preassure Sensor

- power supply voltage : 12~24VDC±10%

- rated pressure range : -0.100 ~ +1.000MPa

Sequence Module Unit)

Molded case circuit breaker

- rated voltage: AC460V

- rated short circuit: 2.5KA

- rated current: 30A

- outer size: 75x96x60mm

Electronic overcurrent relay

- current setting: 3.0 ~ 30A

- operating voltage: 24~240V AC/DC (50/60Hz)

Electromagnetic contactor

- rated current: 32, 40A

- rated operational voltage: 690V

- rated insulation voltage: 1000V

Content Specification

- Rated current : 10A 30VDC / 10A 250VAC

- Max. switching voltage : 250VAC/10A, 2.5VDC/1.5A

Coil specification

- voltage specification: 12VDC, 24VDC, 100/110VDC, 12VAC 50/60Hz, 24VAC 50/60Hz

- Max . cut-off voltage : DC : 10% of rated voltage AC: 30% of rated voltage

- Max. Voltage: 110% of rated voltage

Pneumatic Module Unit)

Single-acting cylinder

- Max. pressure: 1.5MPa/102PSI

- Bore : 10mm/0.39in

- Stroke : 15mm/0.6in

- Road Diameter : 4mm/0.16in

- Weight : 30[g]

Double-acting cylinder

- Max. pressure: 1.5MPa/102PSI

- Bore : 10mm/0.39in

- Stroke : 15mm/0.6in

- Road Diameter : 4mm/0.16in

- Weight : 30[g]

AC In-/output) 220V DC Output) 24V

Training Contents Chapter 1. Summary of PLC Chapter 2. PLC Structure Chapter 3. PLC Wiring and Command Chapter 4. Composition of FX-PLC Chapter 5. GX Developer Operation Chapter 6. PLC Basic Command Chapter 7. PLC Numerical Data Chapter 8. Application Command and Programming Chapter 9. Learning Programming Chapter 10. Sequence Control practice Chapter 11. Sensor Module Control practice Chapter 12. Pneumatic Module Control practice Chapter 13. PLC Application Control Practice

Product name: HMI Training System Model: YPLC-TSO-1000 Feature

■ Rigid aluminum hard case

■ Various communication port built-in (Serial, USB, Ethernet)

■ Supplying high pixel 7.0”, 65536 Color

■ LED backlight TFT LCD

■ Max. 120[MB] screen data saving

■ Able to create simple animation

■ Adopted in the manufacturing plant such as SAMSUNG and LG Electronics and etc. Specification Display unit : 7”wide, color TFT LCD resolution: 800x480 (WVGA) color : 65,536 Power source: DC24V±10% Internal memory: 128MB External memory : USB Serial communication : 1) COM1 : RS-232C 2) COM2 : RS-232C/422A/485 Ethernet communication : 10BASE-T/100BASE-TX

Training Contents Chapter 1. To install Omron Touch Screen Chapter 2. How to use Omron Touch Screen Chapter 3. Omron Touch Screen drawing practice Chapter 4. Drawing practice applied with PLC Trainer

and sequence Chapter 5. Drawing practice applied with PLC Trainer, sequence module and switch module Chapter 6. Drawing practice applied with PLC Trainer, sequence module and switch. sensor module Chapter 7. Drawing practice applied with PLC Trainer, sequence module, sensor, pneumatic module Chapter 8. PLC application control drawing practice

Product name: HMI Training System Model: YPLC-TSP-2000 Feature

■ Rigid aluminum hard case

■ Various communication port built-in (Serial, USB, Ethernet)

■ Supplying high pixel 7.5”, 65536 Color

■ LED backlight TFT LCD

■ Max. 32[MB] screen data saving

■ Able to create simple animation

■ Economic price Specification Display unit : 7”wide, color TFT LCD resolution: 800x480 (WVGA) color : 65,536 Power source: DC24V±10% Internal memory: 128MB External memory : USB Serial communication : 1) COM1 : RS-232C 2) COM2 : RS-232C/422A/485 Ethernet communication : IEEE802.3i/IEEE802.3u, 10BASE-T/100BASE-TX

Training Contents Chapter 1. To install Pro-face Touch Screen Chapter 2. How to use Pro-face Touch Screen Chapter 3. Pro-face Touch Screen drawing practice Chapter 4. Drawing practice applied with PLC Trainer

and sequence Chapter 5. Drawing practice applied with PLC Trainer, sequence module and switch module Chapter 6. Drawing practice applied with PLC Trainer, sequence module and switch. sensor module Chapter 7. Drawing practice applied with PLC Trainer, sequence module, sensor, pneumatic module Chapter 8. PLC application control drawing practice